The benefits of AI technology in the manufacturing industry

In recent years, the digital landscape has changed the way many businesses and industries work. The government’s UK digital strategy lays out the framework for continuing to build on the harnessing of successful digital technology across all sectors.

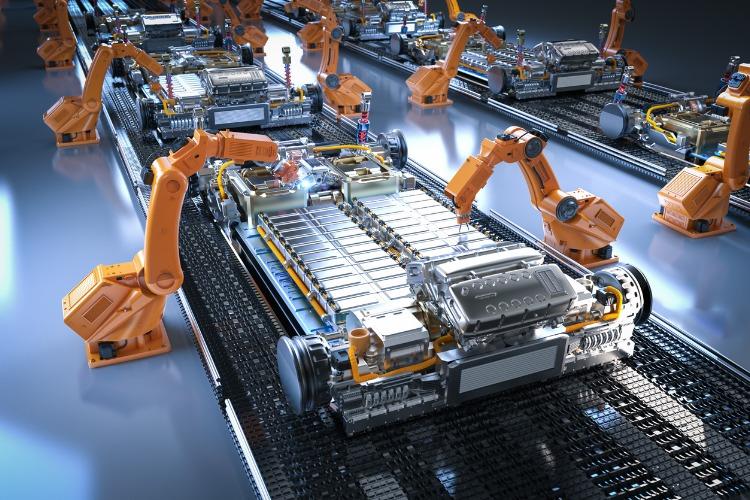

Manufacturing is one industry that is already benefitting from a range of artificial intelligence systems to boost workflow and production.

We’ll take a look at some specific examples across the industry and the advantages of adopting these new ways of working.

What AI technology is being used across manufacturing?

Machine learning, data gathering and automation is rapidly becoming a priority for manufacturing companies to enable efficiency across workflows and processes. For example, BMW are making use of automated image recognition, meaning that quality assurance inspections are easier and more accurate.

Porsche are also making use of AI in the form of autonomous guided vehicles to remove the need for human-led transportation across their plant.

What are the benefits of AI in manufacturing?

There are multiple advantages to using this form of digital technology that can benefit the industry, regardless of the end product. These include:

- Predictive maintenance: This involves using AI technology to predict any issues that might result in the breakdown of machinery. By employing such technology, businesses can easily anticipate when operations systems need to be serviced or replaced. For example, AI can predict when certain components will need to be treated with lubricants such as those from RS.

- Forecasting: AI can help businesses predict supply-demand logistics. This can result in an increase in efficiency, client satisfaction and cost reduction. It can also help predict required staffing levels. This process is also likely to become quicker and even more efficient as the technology ‘learns as it goes’.

- Quality: Utilising this technology removes human error and therefore can increase the overall quality of a product.

- Streamlining workflows: With smarter processes, production can become more efficient, saving both time and money across a business.

- Improved safety: Automation can help improve safety measures due to increased accuracy and the fact that there is less need for human intervention.

- Improved data gathering: Real-time data updates mean operations can benefit from improved and targeted performance as well as faster resolutions and diagnostics.

While many are concerned about AI replacing humans in workplaces such as manufacturing plants, introducing this type of technology actually frees up staff to be able to concentrate on more creative processes. This can lead to significant company growth and success.

Finally, as AI looks to transform the future of the both the UK and global economy, manufacturing businesses should consider implementing this type of technology to remain strong in a competitive market.